Strategic vision

As a system design company, DELTATEC often takes the product packaging in charge, either using standard parts or building a custom solution. When a project calls for this service, the technology is selected on the basis of technical requirements and cost objectives.

For embedded systems, mechanics play an important role in the respect of environmental requirements, typically thermal, EMC, vibration and humidity. Aesthetical aspects are outsourced to partners specialised in this field.

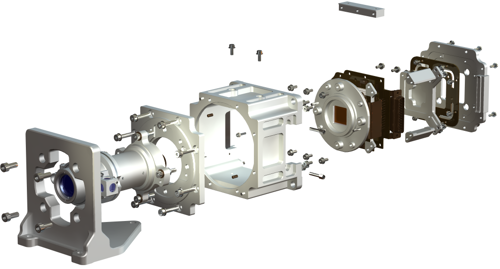

DELTATEC also regularly designs complex mechanical parts in the scope of its activity in the space market, such as enclosures for on-board computers and mechanical supports for on-board cameras. Thermal dissipation and compliance with vibration requirements are usually the main challenges for those designs.

A project with mechanics includes much more than the design of mechanical parts. A lot of simulations, sometimes very complex, have to be performed before manufacturing. Prototype validation is also an important step of the process, through specific tests: EMC, vibration, thermal…

Tools/Method

CAD

Today, most of the mechanical design activities are performed using computer-aided design software. DELTATEC is uses Solidworks as a single solution to cover every aspect of the product development process within an integrated workflow:

- Design - DELTATEC can quickly draw first product design sketches. An interesting feature is our ability to provide realistic pictures of a product in the early stages of its definition

- Simulations - Whether for thermal management or mechanical loads validation (static loads, vibration…), DELTATEC can, before manufacturing, simulate the behavior of the mechanics to validate the design against its environmental constraints

- Manufacturing - The design is checked and verified for manufacturability early in the development process, saving time and development costs. All production-level drawings for the manufacturing of custom parts are created inside Solidworks

- Import / Export - DELTATEC can easily import and export any 3D or 2D mechanical file or drawing

Manufacturing techniques

Partnerships with various subcontractors enable DELTATEC to cover solutions built around the following technologies:

- Machining - Milling and turning mainly for metal (aluminium, titanium, steel…) or plastic materials

- Sheet metal

- Metal and plastic molding

- Rapid prototyping: Additive manufacturing (3D printing, stereolithography, direct metal laser sintering)

- Finishing: Chemical treatments, Painting, digital printing, serigraphy, silk-screened membranes