Client and Partners

MANUNET is a network (ERA-NET) funded by the European Commission. Since 2006 MANUNET has been working with the objective to promote and fund transnational research and development projects in the field of manufacturing, through yearly calls for proposals.

Partners

- TECNOCIM: created in 1988 to provide software products and services for industries where CAD/CAM software for Robots is one of its major business lines.

- NOGUERASA: a capital goods manufacturer, its origin dates back to 1912. The company expertise is focused in the maintenance and manufacture of metal industry goods and the robotic cutting plasma section is one of most important within its structure.

- INFOBOTICA: a research group at University of Oviedo in Spain, Asturias.

- BDIGITAL: an advanced technology centre in the field of ICTs from Spain, Catalonia.

Project

Advanced system for increasing industrial quality on robot traces applied to Plasma Arc Cut systems (PACs).

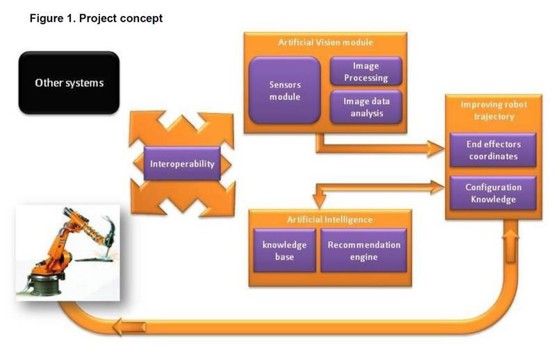

CUTROB+ proposes the combination of computer vision, interconnectivity, artificial intelligence and CAD/CAM data for improving robot trajectories by recommending the general parameters that influence in the configuration of different applications, reduce On line Programing (OLP) setup time and advance in the possibility to perform path tracking at low cost.

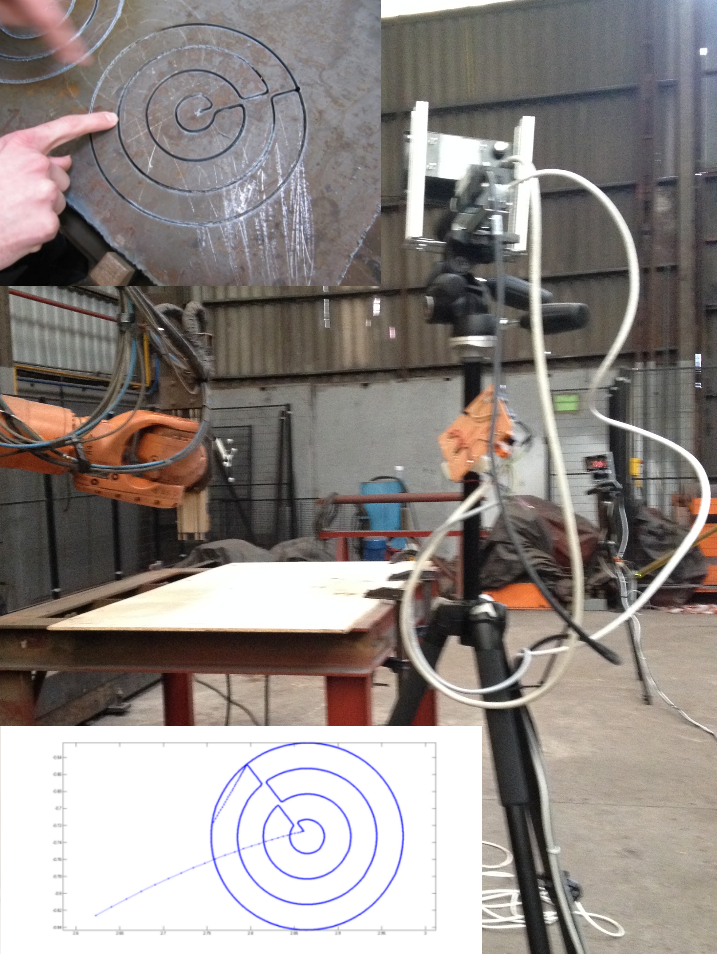

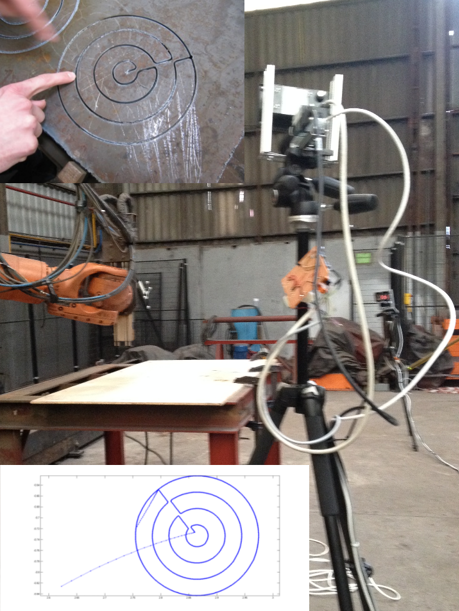

DELTATEC is in charge of the computer vision system. The goal is to provide information about the position of the end-effector to correct the robot movements and improve the quality of the cut. This includes the development of a robotic arm tracking system to estimate the end-effector position during the offline (with torch switched off) simulation of plasma cutting.

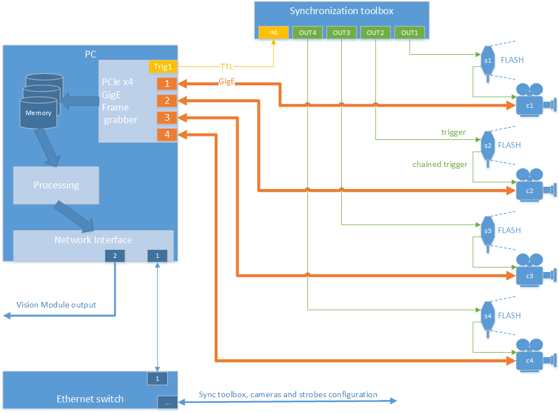

- The vision system setup

2. The estimation of the 3D positions of a pattern place on the robot end effector while the robot is moving

Challenges

The main challenges are:

- Selecting the right set of cameras, strobes, lenses, filters and targets for the aimed industrial environment

- Synchronizing the images capture from all used cameras

- Presenting an ergonomic user interface and system to allow any user to run all the needed operations

- Implementing specific and state of the art image processing to reach 3D position detection of a pattern with very high precision (sub-pixel precision) even in the constraining industrial environment

- Optimizing the image processing for minimal latency

Solutions

Thanks to its large image processing experience, DELTATEC was able to propose and develop a complete solution to achieve the goals.

Finally, the solution includes the incoming video capture, the cameras calibrations processes, the 3D pose estimation process and output data streaming over IP in a single ergonomic application.